Products

Confectionery and Line Automation

Confectionery refers to the manufacturing and sale of sweets and desserts, including chocolates, candies, pastries, and other sugary treats. Line automation, on the other hand, refers to the use of automated systems and technologies to streamline and optimize production processes on assembly lines.

- Automated Mixing and Batching: Automated systems can be used to precisely measure and mix ingredients for confectionery products. This ensures accurate and consistent recipes, reduces human error, and increases production speed.

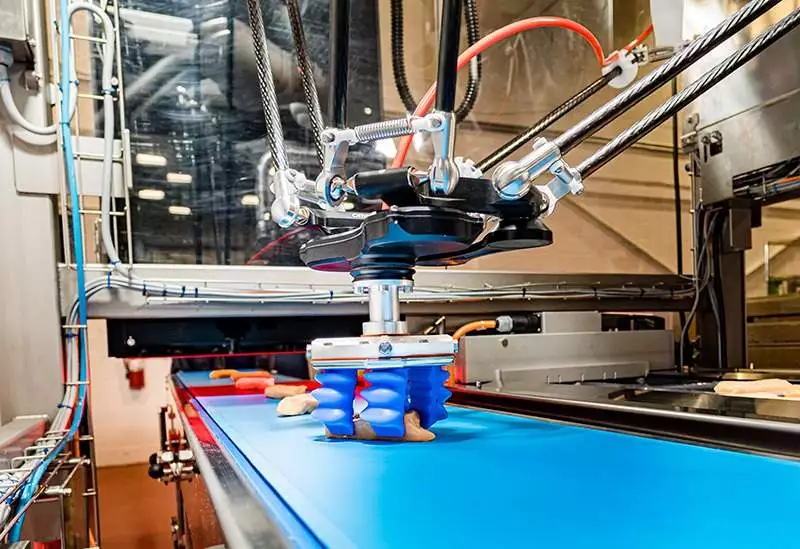

- Robotic Packaging: Robots can be employed to automate the packaging process by picking and placing confectionery items into boxes, bags, or trays. They can handle delicate items without damaging them and maintain high packaging speeds.

- Quality Control: Automation can be utilized for quality inspection and control. Vision systems equipped with cameras and sensors can detect defects, such as misshapen candies or improper packaging, and remove them from the production line.

- Product Handling: Automated conveyors and material handling systems can transport confectionery products between different stages of production. They can transfer goods between machines, sort items based on size or weight, and facilitate smooth workflow.

- Inventory Management: Automated systems can monitor and manage inventory levels of raw materials, packaging materials, and finished products. This helps optimize supply chain management and reduces the risk of stockouts or overstocking.

- Data Analysis and Optimization: Automation allows for the collection and analysis of production data, such as machine performance, production rates, and quality metrics. This data can be used to identify bottlenecks, optimize processes, and make informed decisions for continuous improvement.